It’s that time of year again – the season of pumpkin spice everything, football games filling our weekends, and a prime opportunity to save on energy costs using air and water-side economizers. As temperatures drop during cool fall mornings (typically between 45-55°F), facilities have an excellent chance to leverage natural cooling to reduce mechanical refrigeration needs. Implementing and maintaining these economizer systems can result in substantial energy savings while also extending the life of HVAC equipment. Let’s dive into how economizers work and explore additional tips to optimize them this season.

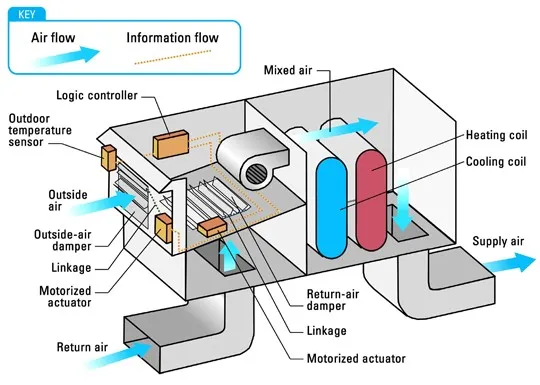

Understanding Air-Side Economizers

Air-side economizers take advantage of the cool outside air to provide free cooling for buildings, significantly cutting down on the use of traditional air conditioning. When outside air temperatures are lower than the desired indoor temperature, air-side economizers allow fresh air to be brought in, mixed with the return air, and circulated throughout the building, reducing the need for mechanical cooling.

Here are a few maintenance tasks and checks to ensure your air-side economizer operates at peak performance:

- Inspect Outside Air Dampers: Verify that the outside air dampers open and close properly according to control commands.

- Check Relief/Exhaust Dampers: Just as the intake dampers need to work properly, relief or exhaust dampers must also function smoothly to maintain the building’s pressure balance.

- Calibrate Sensors: Temperature and humidity sensors are vital for economizer operation, as they determine when to open the economizer dampers.

- Control Sequence Verification: Ensure the economizer control sequences are properly set up and functioning.

Leveraging Water-Side Economizers

Water-side economizers provide another energy-saving opportunity, especially for facilities equipped with cooling towers. As outside temperatures drop, cooling towers can cool water to lower temperatures without the need to operate chillers. Water-side economizers typically work by using the cooling tower water to precool the chilled water supply or to bypass the chiller altogether under the right conditions.

To maximize the benefits of water-side economizers, keep these tips in mind:

- Monitor Condenser Water Temperatures: Cooler outdoor temperatures should result in lower condenser water temperatures.

- Clean Cooling Towers and Strainers: Cooling towers can collect leaves and debris during the fall season, which can reduce their efficiency.

- Use Variable Speed Drives on Pumps and Fans: Adjusting the speed of pumps and fans can significantly reduce energy consumption.

- Take Advantage of Integrated Controls: Many modern systems have integrated control capabilities that allow both air and water-side economizers to work together seamlessly.

Additional Tips for Optimizing Economizer Performance

- Conduct a Fall Maintenance Check: As temperatures begin to drop, schedule a thorough inspection of your HVAC system, including both air and water-side economizers.

- Install Economizer Fault Detection and Diagnostics (FDD): Economizer FDD systems can automatically detect common issues like sensor failures, damper malfunctions, or improper control sequences.

- Implement Night Purge Strategies: In addition to standard economizer use, consider implementing a night purge strategy during fall and spring when temperature swings are common.

- Regularly Review Trend Data: Take advantage of building automation systems to track economizer performance data over time.

Fall is an ideal time to optimize your economizer systems, taking advantage of cooler temperatures to reduce reliance on mechanical cooling and save energy. Whether you are using air-side or water-side economizers, regular maintenance, proper control setup, and monitoring can make a substantial difference in energy efficiency. By following these tips, you can ensure your economizers are operating at peak performance.